The ISE curriculum explicitly encompasses coursework useful in addressing not only the technical elements of work systems, but also the organizational, economic, and human elements. Our aim is to provide graduates with the knowledge and capabilities to enable them to successfully pursue careers in industrial engineering or, if qualified, to continue on to graduate study.

ISE emphasizes instruction in fundamental engineering principles based on the physical sciences, engineering sciences, mathematics, and statistics. These principles are applied in practical design experiences throughout the undergraduate curriculum.

Course work in the physical and chemical sciences and mathematics provides a solid background for basic engineering science courses, which in turn support more focused courses in industrial engineering, covering topics in operations research, manufacturing systems engineering, human factors engineering and ergonomics, and management systems engineering. In all these areas, analysis and design activities are supported by modern computing and software tools taught in the curriculum.

Students gain valuable hands-on, laboratory experience in manufacturing processes, work methods, computer simulation, and human factors engineering. State-of-the-art laboratory facilities associated with the undergraduate curriculum include the ISE Computer Laboratory, which contains computers and printers to support the needs and requirements of ISE students that are not available through access to personal computers or in other laboratories; the Senior Design Center, with computer support and other resource material for student design projects; the Harris Manufacturing Processes Laboratories, which contain robotics and automation equipment, machining equipment, conventional and numerically controlled machine tools, and welding and foundry facilities; the Human Factors Work Measurement and Methods Engineering Laboratory, which is equipped and used for in-class exercises and experiments in work measurement, motion economy and time study, psychophysics, human audition and vision, and work station design.

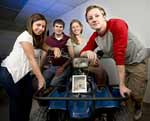

The capstone course in the ISE Undergraduate Program is a two-semester class, ISE 4005-6 Project Management & System Design (also referred to as “Senior Design”), where students work in project teams with an external company sponsor to solve a real-world problem. This experience provides ISE students with actual project experience that develops technical and professional skills, such as teamwork, communication, project management, and life-long learning skills, in addition to developing capabilities in applying IE tool and techniques. Student project teams present their project findings at our annual Senior Design Symposium attended by company sponsors and the ISE Advisory Board.

For the 2015 graduation requirements, the course work totals 136 hours. Electives provide students with the opportunity to explore other areas of engineering, as well as cultural, societal and creative experiences, which makes for a well-rounded, diverse, and globally-aware engineer.

The ISE program also provides students with the opportunity to pursue minors, such as a Business Minor, Green Engineering Minor, or Math Minor. More specific information about minors available to ISE students can be found in the ISE Undergraduate Student Handbook, posted on the ISE web site. Students and employers alike are seeing the benefits of these minors for adding value to the ISE major.

Many ISE students seek to participate in Undergraduate Research to satisfy elective requirements in the curriculum. The opportunity to work more closely, in some cases on a one-on-one basis, with our outstanding faculty can provide more in-depth development of ISE capabilities and a more enriching educational experience.

The department participates in the Cooperative Education Program, in which qualified students may alternate semesters of study with semesters of professional co-op employment or internships. Students are encouraged to pursue these experiences before they graduate to make them more competitive in the work force. Students are also encouraged to participate in career fairs and job interviews on and off campus.

The ISE department also provides students with many significant scholarship opportunities at the undergraduate and graduate levels to encourage and acknowledge high academic performance and achievements.

The ISE department also maintains bilateral student exchange agreements with international universities, where students can take ISE courses which will transfer back to their BSISE. Students may also select other universities at which to perform a study abroad semester.

Graduate programs leading to the M.S. and Ph.D. are offered (see Graduate Catalog). The graduate programs include concentrations in manufacturing systems engineering, human factors engineering and ergonomics, operations research, management systems engineering, and general IE. The ISE Department also coordinates on- and off-campus master's degree programs in systems engineering (M.S.) and engineering administration (M.E.A.).

Undergraduate Course Descriptions (ISE)

2004: INTRODUCTION TO INDUSTRIAL AND SYSTEMS ENGINEERING

Introduction to the industrial and systems engineering profession through exposure to problems, principles, and practice. Integrated systems approach to problem solving. Foundation of data manipulation and preparation for problem analysis. Development of communication skills, career opportunities, importance of professionalism, ethics, contemporary challenges, lifelong learning, and introduction to the ISE Department. C- or better required in ENGE 1104 or ENGE 1114 or ENGE 1434. Pre: ENGE 1104 or ENGE 1114 or ENGE 1434. (1H,3L,2C)

2014: ENGINEERING ECONOMY

Concepts and techniques of analysis for evaluating the value of products/services, projects, and systems in relation to their cost. Economic and cost concepts, calculating economic equivalence, comparison of alternatives, purchase versus lease decisions, financial risk evaluation, cash flow sensitivity analysis, and after-tax analysis. Pre: ENGE 1024. (2H,2C)

2034: DATA MANAGEMENT FOR INDUSTRIAL AND SYSTEMS ENGINEERS

Investigation of data modeling, storage, acquisition, and utilization in industrial and systems engineering via manual and computerized methods. Development of effective of effective spreadsheet applications. Design and implementation of relational databases via entity-relationship modeling, relational schema, and normalization. Web-based database applications. Interface design and the system development life cycle applied to data management applications. All topics covered within the context of typical industrial and systems engineering problems.

Pre: 2004, 2214, (ENGE 2314 or CS 1044). (3H,3C)

2204: MANUFACTURING PROCESSES

Survey of manufacturing processes including casting, forming, machining, welding, joining, and nontraditional processes such as laser-beam and electrical-discharge machining. Basic structure of metals, physical, and mechanical properties and their relationship to manufacturing. Process planning and the effect of plans on cost, safety, and the environment. Impact of product design on manufacturability: design for manufacture, assembly, etc. Also include topics in inspection and testing, jigs and fixtures, and numerical control. C- or better required in ENGE 1104 or ENGE 1114 or ENGE 1434. Pre: ENGE 1104 or ENGE 1114 or ENGE 1434. (3H,3C)

2214: MANUFACTURING PROCESSES LABORATORY

Laboratory exercises and experimentation in manufacturing processes. Emphasis on using production machines and equipment to make products using multiple manufacturing processes, coupled with inspection per engineering drawings. Processes include assembly, casting, machining, forming, welding, and non-traditional machining, performed manually and/or via computer programming. Also covers basic shop floor operation and documents used for monitoring and controlling part production. C- or better required in ENGE 1104 or ENGE 1114 or ENGE 1434. Pre: ENGE 1104 or ENGE 1114 or ENGE 1434. (3L,1C)

2404: DETERMINISTIC OPERATIONS RESEARCH I

Deterministic operations research modeling concepts; linear programming modeling, assumptions, algorithms, modeling, languages, and optimization software; duality and sensitivity analysis with economic interpretation; network models (formulations and algorithms), including transportation problems, assignment problems, shortest path problems, maximum flow problems, minimum cost network flow problems, minimal spanning tree problems. Co: MATH 2224. (3H,3C)

2984: SPECIAL STUDY

Variable credit course.

2994: UNDERGRADUATE RESEARCH

Variable credit course.

3004: INDUSTRIAL COST CONTROL

Fundamentals of general and cost accounting practices applied to manufacturing and service organizations. Cost accounting, standard cost determination, cost and budgetary control systems. A grade of C- or better required in prerequisite ISE 2014. Pre: 2014 or ME 2024. (4H,3C) II.

3014: WORK MEASUREMENT AND METHODS ENGINEERING

Survey of methods for assessing and improving performance of individuals and groups in organizations. Techniques include various basic industrial engineering tools, work analysis, data acquisition and application, performance evaluation and appraisal, and work measurement procedures. A grade of C- or better required in prerequisites ISE 2204 and 2214 and STAT 4105. Pre: (2204 or 2214), STAT 4105. (2H,3L,3C) I,III.

3214: FACILITY PLANNING AND MATERIAL HANDLING

Theory, concepts, and methods for designing and analyzing facilities and material flow in manufacturing, storage, and distribution environments. Topic areas include material handling systems, facility layout, facility location, warehousing, distribution, logistics, and transportation. Pre: 2014, 2404, 3414. (3H,3C)

3414: PROBABILISTIC OPERATIONS RESEARCH

This course introduces probability models used to investigate the behavior and performance of manufacturing and service systems under conditions of uncertainty. Major topics include probability, conditioning, elementary counting processes, and Markov chains and Markov processes. Emphasis is on the use of these tools to model queues, inventories, process behavior, and equipment reliability. Pre: STAT 4105, MATH 2224, (MATH 2214 or MATH 2214H), (ENGE 2314 or CS 1044). (3H,3C)

3424: DISCRETE-EVENT COMPUTER SIMULATION

Analysis and design of work systems through static and dynamic simulation. Topics include an introduction to systems analysis and modeling, simulation optimization, model development, and testing, and problem analysis through simulation. Pre: 3414, STAT 4105. (2H,3L,3C)

3434: DETERMINISTIC OPERATIONS RESEARCH II

Advanced concepts in deterministic operations research, including theory of complexity, integer programming, advanced linear programming techniques, non-linear programming, dynamic programming. Covers modeling languages and optimization software for integer programming and nonlinear programming problems. Pre: 2404, MATH 2224. (3H,3C)

3614: HUMAN FACTORS AND ERGONOMICS ENGINEERING

Investigation of human factors, ergonomics, and work measurements engineering, with emphasis on a systems approach toward workplace and machine design. Discussion of basic human factors research and design methods, design/evaluation methods for work systems and human machine interactions, human information processing, visual and auditory processes, display and control design, and effects of environmental stressors on humans. Pre: (2204 or 2214), STAT 4105. (3H,3C)

3624: INDUSTRIAL ERGONOMICS

Introduction to ergonomics and work measurement with an emphasis on people at work. Discussion of methods for work measurement, ergonomic assessment, and evaluation, with major topics including productivity and performance, manual materials handling, work related musculoskeletal disorders, safety, training and legal issues. Pre: 3614, ESM 2104. (3H,3C)

4004: THEORY OF ORGANIZATION

A theory of cooperative behavior in formal organizations, including the structure and elements of formal organizations. The executive process and the nature of executive responsibility also are examined. I, II.

(3H,3C)

4005-4006: PROJECT MANAGEMENT AND SYSTEMS DESIGN

4005: Capstone design experience for ISE majors. Structured systems engineering and project management methods and tools to plan, manage, and execute technical industrial and systems engineering projects. Students work in teams to apply industrial and systems engineering and project management tools to define and analyze a real-world problem. 4006: Continuation of capstone design experience for ISE majors. Designing, implementing, and evaluating work system solutions. Communication of solutions to various project stakeholders. Pre: 2204, 2214, 3024, 3214, 3424, 3624 for 4005; 4005, 4204 for 4006. 4005: (3H,3C) 4006: (2H,2C)

4015,4016: MANAGEMENT SYSTEMS THEORY, APPLICATIONS, AND DESIGN

Systems approach to management, domains of responsibility, structured and synergistic management tools, management system model, contextual frameworks, information portrayal, automation objectives model, evaluation, shared information processing, information modeling. A management process for definition, measurement, evaluation and control, the organization as an information processor, corporate culture, scoping agreements, schemas and management elements, structured design. I. (3H,3C)

4204: PRODUCTION PLANNING AND INVENTORY CONTROL

Planning and control of operations in both manufacturing and service industries. Effective management and utilization of resources and the production of cost effective products and services. Principles, models, and techniques used for production planning and inventory control.

Pre: 2404, 3414, STAT 4706. (3H,3C)

4214: LEAN MANUFACTURING

Overview of Lean Manufacturing principles, theory, methods, and techniques in modern manufacturing enterprises. Lean philosophy and basic concepts, master production scheduling and production smoothing, assembly line sequencing, setup time reduction, U-shaped line balancing/operation, machine arrangement, Kanban, autonomation, and value stream mapping. Investigation and discussion of lean manufacturing case studies. Pre: 4204. (3H,3C)

4264: INDUSTRIAL AUTOMATION

A survey of the various technologies employed in industrial automation. This includes an emphasis on industrial applications of robotics, machine vision, and programmable controllers, as well as an investigation into problems in the area of CAD/CAM integration. Examination of the components commonly employed in automation systems, their aggregation and related production process design. Laboratory work is required. A grade of C- or better required in prerequisites ISE 2204 or 2214. Pre: 2204 or 2214. (2H,3L,3C)

4304: GLOBAL ISSUES IN INDUSTRIAL MANAGEMENT

Industrial management topics of current interest explored from a global perspective. Current domestic and international challenges resulting from a global marketplace and the proliferation of information and technology. Industrial management and organizational performance, total quality management, business process re-engineering, leadership, organizational change, role of communication and information, and ethics. Examination and comparison across international boundaries. (3H,3C) II.

4404: STATISTICAL QUALITY CONTROL

Application of statistical methods and probability models to the monitoring and control of product quality. Techniques for acceptance sampling by variables and attributes are presented. Shewhart control charts for both classes of quality characteristics are examined in depth. The motivation for each method, its theoretical development, and its application are presented. The focus is upon developing an ability to design effective quality control procedures. A grade of C- or better required in ISE 3414, STAT 4105, and STAT 4706. Pre: 3414, STAT 4105, STAT 4706. (3H,3C) I.

4414: INDUSTRIAL QUALITY CONTROL

Implementation of statistical quality control techniques in an industrial setting. Development and analysis of cost models for use in the design of optimal quality control plans. Also included are new techniques, advanced quality control models, and an examination of the role of industrial statistics in the overall product quality assurance function. A grade of C- or better required in prerequisite ISE 4404. Pre: 4404. (3H,3C)

4424: LOGISTICS ENGINEERING

Introduction to the key issues in the integrated support of a product of process. Synthesis of topics from earlier studies to provide a cohesive approach to their applications. Logistics engineering provides a survey of product support issues and methods of resolving them within the context of the overall production activity. A grade of C- or better required in prerequisite ISE 3414. Pre: 3414. (3H,3C)

4624: WORK PHYSIOLOGY

Anthropometry, skeletal system, biomechanics, sensorimotor control, muscles, respiration, circulation, metabolism, climate. Ergonomic design of task, equipment, and environment. A grade of C- or better required in prerequisite ISE 3614. Pre: 3614 or 3624. (3H,3C)

4644: OCCUPATIONAL SAFETY AND HAZARD CONTROL

Survey of occupational safety. Topics include: history of occupational safety; hazard sources related to humans, environment, and machines; engineering management of hazards. A grade of C- or better required in prerequisite ISE 3614. Pre: 3614. (3H,3C) II.

4654: PRINCIPLES OF INDUSTRIAL HYGIENE

Introduction to the foundations of the field of Industrial Hygiene, that discipline devoted to the anticipation, recognition, measurement, evaluation, and control of occupational health hazards. Includes biological (e.g. microbial agents, allergens), chemical (e.g. solvents, carcinogens, dusts), and physical (e.g. radiation, temperature) hazards. Overview of control of health hazards, such as personal protective equipment, administrative controls, and engineering controls. Will involve lecture and participatory "case-study" activities. Will provide ample opportunity for hands-on use of monitoring equipment, protective equipment and controls testing devices. II. (3H,3C)

4974: INDEPENDENT STUDY

Variable credit course.

4984: SPECIAL STUDY

Variable credit course.

4994: UNDERGRADUATE RESEARCH

Variable credit course.

TOP